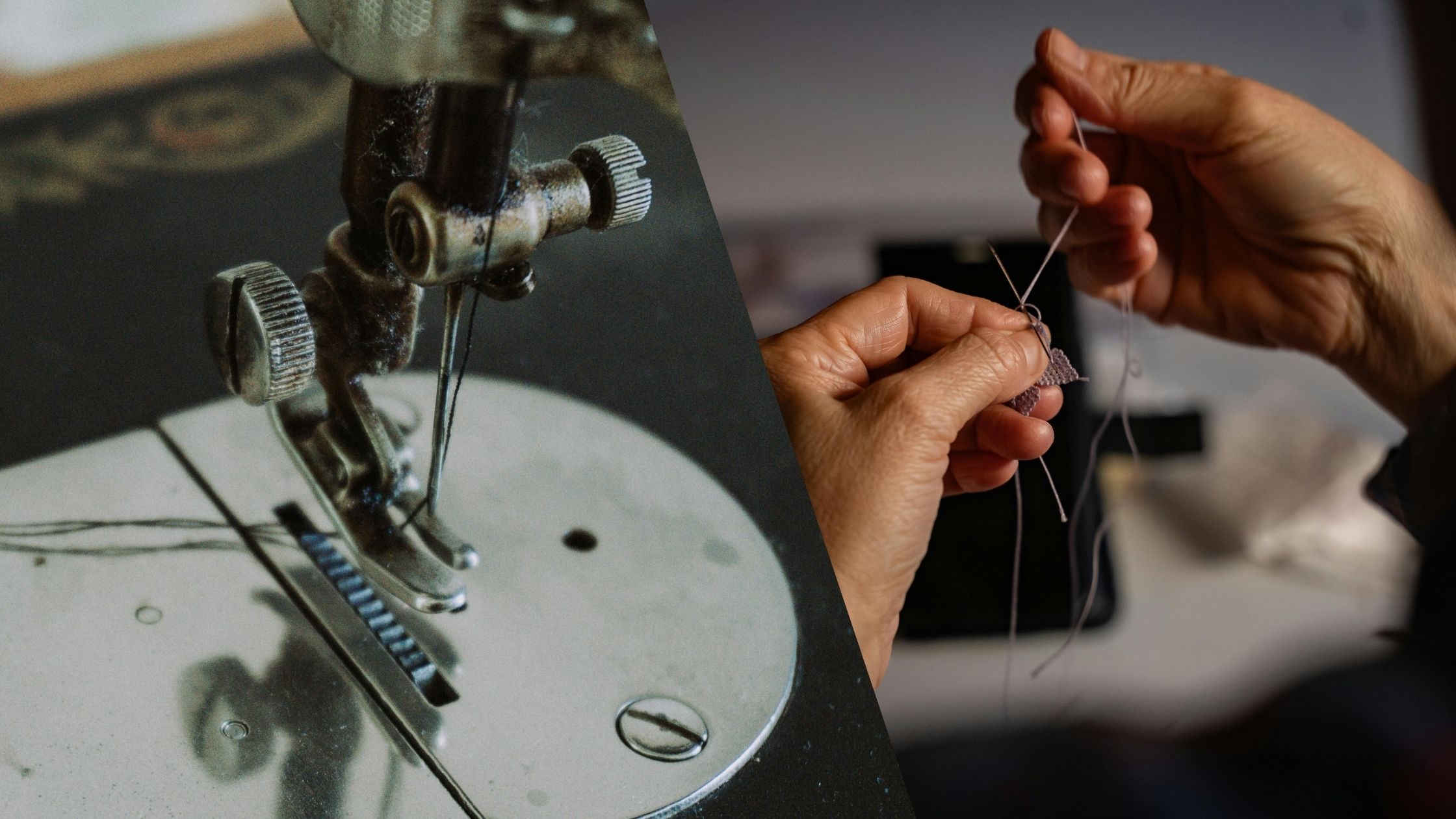

Embroidery thread is not the same as regular sewing thread in purpose or feel, and this distinction influences how you stitch, finish, and even select your tools. It shines, flows smoothly, and behaves differently under tension, which is important when deciding what to put together and how it will wear. The contrast behind the seams raises questions to consider as you plan your next project.

What Embroidery Thread is and How it’s Used

Embroidery thread is a decorative option designed mainly for embellishing fabric with machine-driven stitches. You use it to add flair through embroidery techniques that suit fast, reliable machine work.

Choose threads with proper thread compatibility for your device and fabric, then adjust machine settings to prevent breaks or skipped stitches. Consider design elements and how stitch density affects appearance and durability.

Color selection matters; you’ll pick bright or metallic tones to enhance logos, monograms, or motifs. Remember, embroidery thread isn’t meant for seams, so save it for decorative areas and maintain proper tension and speed for clean results.

What Sewing Thread Is and Its Main Functions

Sewing thread is the workhorse of fabric construction, mending, and finishing touches. You use it to join pieces, reinforce seams, and endure regular wear.

Its main functions include construction sewing, repair techniques, and safety stitching, ensuring garments stay intact through washing and use. Adjust thread tension to achieve balanced stitches that don’t pucker or gape.

Different stitch types—straight, zigzag, backstitch, and overlock—serve distinct purposes, from sturdy seams to fine finishing. Garment longevity hinges on choosing the right weight and fiber.

For durable results, match thread to fabric, keep tension correct, and test stitches before sewing.

Material Variations: Fibers Found in Embroidery vs. Sewing Threads

Various fibers power embroidery and sewing threads, and the choice matters for look, strength, and performance. You’ll encounter a range of options: natural blends, sustainable fibers, and synthetic blends all affect sheen, texture, and durability.

Embroidery often leans toward bright, continuous-filament fibers for gloss and minimal lint, while sewing threads favor balanced blends for seam strength. Consider allergen considerations if sensitivities arise, and note dye fastness varies by fiber type and finish.

For care instructions, polyesters or cotton-poly blends typically survive washing cycles better than delicate natural fibers. Choose wisely to match fabric, stitch, and end-use.

Construction and Texture: Filament vs. Staple Materials

Filament and staple materials define how embroidery and sewing threads behave on fabric.

Filament threads are long, continuous strands that provide a smooth finish with consistent surface gloss, whereas staple threads are short fibers that can add texture and body.

When you run embroidery at high speed, filament longevity helps resist fraying and keeps stitches even, yet stiffness can affect drape.

On sewing projects, staple fraying may occur at edges unless carefully reinforced.

Surface grip varies: filaments often glide, and staples grab slightly more.

Your machine tension must suit the material to prevent skipped stitches or puckering.

Thread Weights and Their Typical Applications

Thread weights indicate thickness and affect both look and durability, so choosing the right weight for your project matters. You’ll match weight to fabric, stitch density, and machine capabilities.

For embroidery, lighter 40–60 weight threads create fine detail, while heavier 30–12 weight options build bold, textured seams. In sewing, 40-weight is common for garment construction and quilting, with 50-weight preferred for delicate seams.

Consider spool size and bobbin choice to prevent tangles, and adjust thread tension to avoid puckering. Check needle compatibility, as thicker threads need larger needles for smooth feeding and accurate stitches.

Visual Qualities: Sheen, Finish, and Practical Considerations

Embroidery thread immediately catches the eye with its higher sheen and glossy finish, especially the metallic and rayon varieties that shimmer as they move. You’ll notice light reflection that can dominate designs, so you choose carefully where embroidery shines most.

Matte options exist, offering a subtler look for delicate fabrics or text; they reduce glare while preserving color. Compare colorfastness differences; embroidery often lasts well, but exposure to the sun or washing can alter gloss.

For surface texture, metallic sparkle adds drama, while smooth threads glide quietly. Consider practicalities: thread weight, stitch density, and fabric type to balance shine with durability.

Elevate Every Stitch with Affordable Digitizing

You’ve seen how embroidery thread brings brilliance and texture to designs, while sewing thread delivers lasting strength where it matters. The real magic happens when both are used with intention—and that’s where Affordable Digitizing makes all the difference. With decades of hands-on embroidery experience, thousands of successfully digitized designs, and a passion for clean, efficient stitch paths, our team transforms your artwork into production-ready files that run smoothly, reduce thread breaks, and showcase the sheen of embroidery thread exactly as intended.

At Affordable Digitizing, you get more than a file—you get expertise tailored to your fabric, thread choice, and machine needs. We optimize stitch counts to save you time and money, ensure crisp details at the right densities, and provide quick turnarounds with dedicated support. Whether you’re outfitting a business, launching a brand, or personalizing gifts, our precision-driven approach helps your stitches sing while your seams stay secure.

Choose wisely. Choose a partner who knows how to make thread do its quiet, dependable work behind the art. With Affordable Digitizing by your side, your designs run cleaner, look sharper, and deliver the professional finish your customers will notice—and remember.